Types of Formwork systems

The following are the main types of forms used on the building

Permanent Forms

These are left in place to remain as an integral part of the structure. These forms perform the function of protecting the cast element from external agents. Hence these must be durable and strong. Commonly used materials include:

- Corrugated Steel

- PVC (Poly Vinyl Chloride)

- Carbon/epoxy thin shell

These are more costly due to their single use life. But they accrue benefits in the form of better performance of the structure.

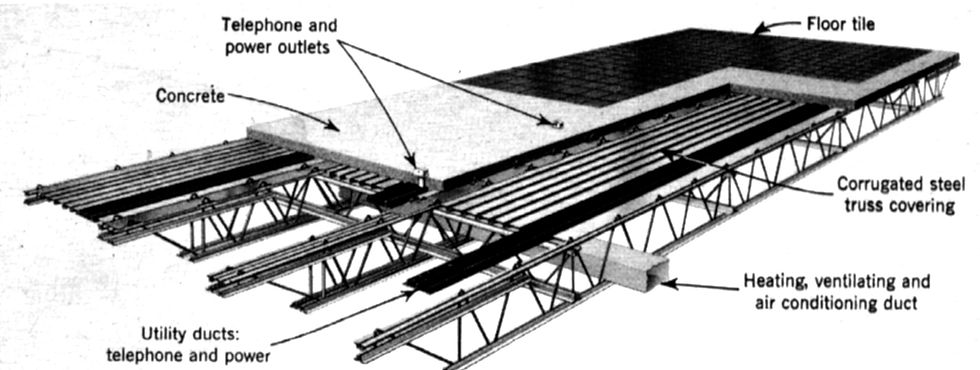

These are built in place using plywood for sheathing and lumber for studs and wales

Her the lateral ties between the two faces hold the concrete in position and create a uniform finish.

This formwork reduces the erection time by considerable system by using an uniform tie system. For additional support , the inclined shores are used.

These are built in place using plywood for sheathing and lumber for studs and wales

Wall Forms

Wall forms are very versatile vertical formwork which when put into place allow the casting of wall with its openings in a monolithic structure.

This increases the life of the structure and reduces the construction time as the wall for the entire floor is generally cast all at once.

These are generally made up of Plywood, Lumber, Aluminum or Steel.

Column Forms

Column forms are one of the versatile forms which facilitate large volumes of concreting in various shapes for RCC columns. In any structure, the casting of columns requires high precision to ensure structural stability.

Nowadays using metal forms, highly efficient shapes of columns can be achieved. Due to large volume of concreting, column forms are generally so designed to resist lateral loads.

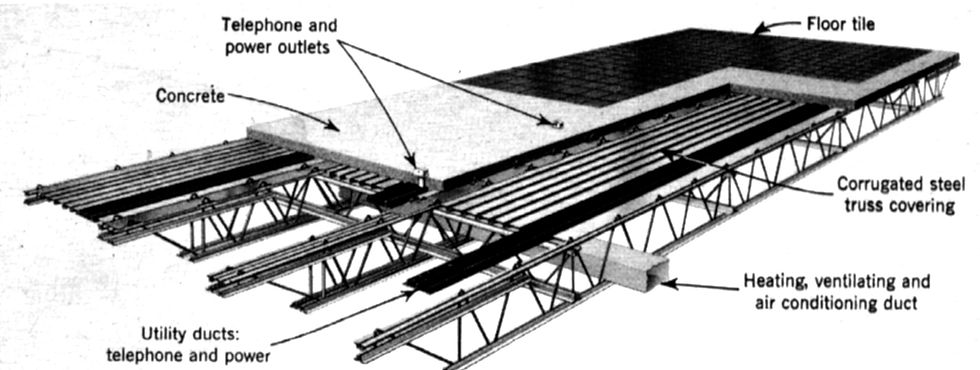

Forms for Floor slabs

This is a common formwork system assembled from standard components. The Floor Slab form facilitates casting of the flexure member monolithically. The support mechanism for te slab formwork may contain a grid of beams or trusses.

When used for RCC framed structures, this formwork allows casting of both Slab and beams simultaneously.

One of the variations of formwork for floor slabs is using inverted plastic domes to cast a grid of beams along with the slab instead of a regular flat panel.

Bridge Deck forms

Nowadays, due to advancement in technology, it is possible to cast complex cross sections of bridge deck using custom formwork. This greatly increases cost savings.

Bridge deck construction has been greatly accelerated with the help of slip forms.

Tunnel forms

The tunnel formwork is an inverted U shaped structural steel fabricated form which is used to cast the RCC walls and floor slabs together in a continuous pour. The forms are then heated using hot air blowers for accelerated curing of the concrete. This system is most economical when the structure consists of large number of identical units.

The steel units are generally assembled on site and then erected. After casting for one unit, the Steel deck is moved horizontally using cranes to cast the next unit.

Flying forms

These are designed to cast large repetitive floor slabs in high rise construction. These are also called as Table forms. When a particular floor slab has been cast, these forms consisting of panels along with the vertical supports are moved as one piece and lifted to the next floor and placed in position. This greatly saves time of disassembling and assembling components. These are specially designed to work a single unit.

Sliding or Slip forms

Slip form means a continuously moving form, moving with such a speed that concrete when exposed has already achieved enough strength to support the vertical pressure from concrete still in the form as well as to withstand lateral pressure caused by wind [3].

The main advantage of this technique is the continuous productivity of the equipment.

This helps in achieving faster project completion. However, for the form to be moving continuously, the mechanism for moving the massive forms is often very complex and accounts for high costs.

It is used mainly for continuous vertical components like shafts or horizontal structures like tunnels.

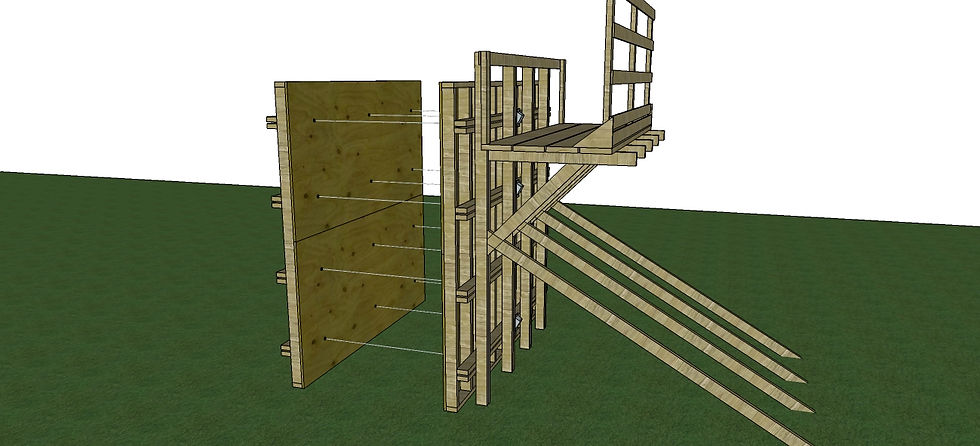

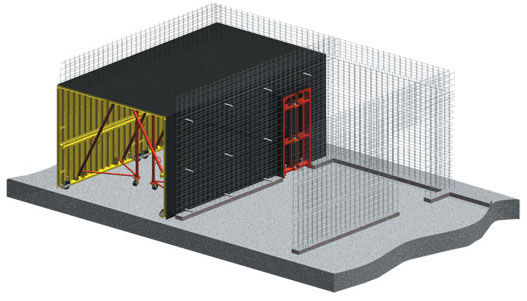

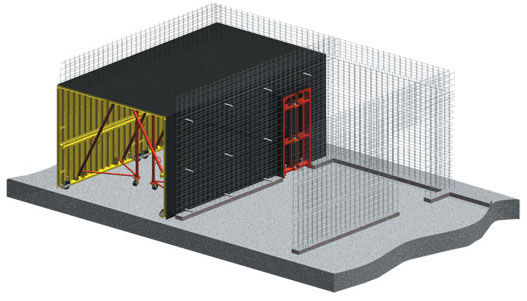

Gang forms

The increasing pace in the construction of multi-storey and massive concrete structures, and the parallel progress in development of cranes and other mechanical methods of transporting forms have made the use of ganged prefabricated forms for the concreting of large sections of high walls very common[3]

Gang forms facilitate efficient casting of vertical components at multiple levels along with providing a secure working platform to increase productivity and reduce accidents. The size of such forms is limited only by the lifting capacity.

Special forms

With increasing complexity in designs of sturcture there is an increasing demand for custom made forms which provide aesthetic appearance. These forms are gradually becoming popular in the market for their versatility for catering a wide range of demands for finished concrete. The casts for such forms are generally made to order.